I have this tyre rubbing marks at the side of my rear Fender .This is my second fender attached to my SX 18 inch Rear tyre.I am wondering what is causing this ?The wheel seemed to be fine without sign of bearing wear and been using my strida since mid- November 2013. This a bit strange .My tyres are all Innova 18".

Most of us will not be able to compare; fixing that was easy…

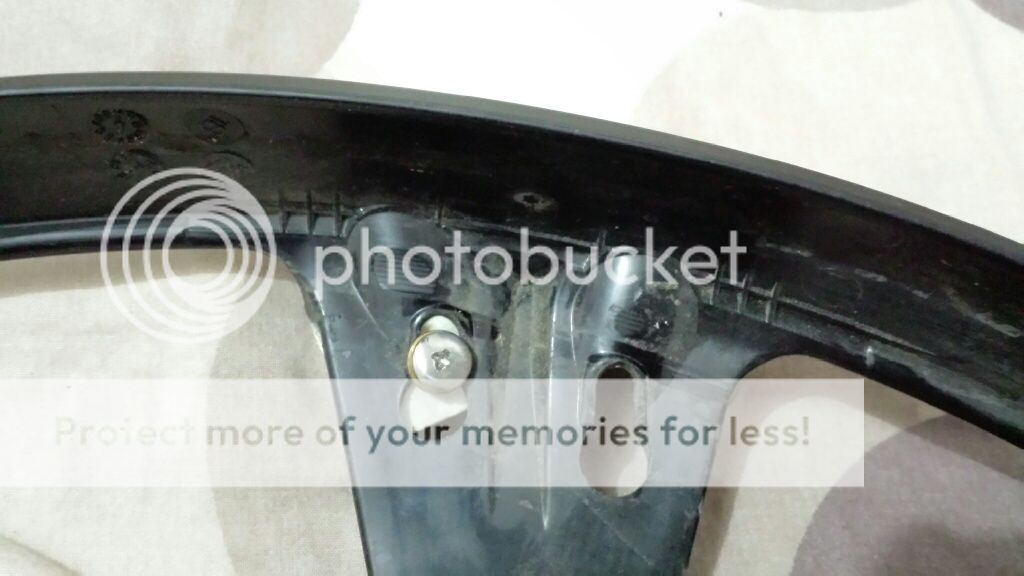

So, the tyre profile grinded the two areas A, the little sideways rubber spikes created the marks in the direction of arrow B and even the surface of the bolt was in touch with the tyre (correct?) - really odd!

I’d like to compare our wheels; you wouldn’t need to disassemble anything,

just the measuring method is a bit tricky and will require some explanation.

A helpful hand might be also recommendable ![]()

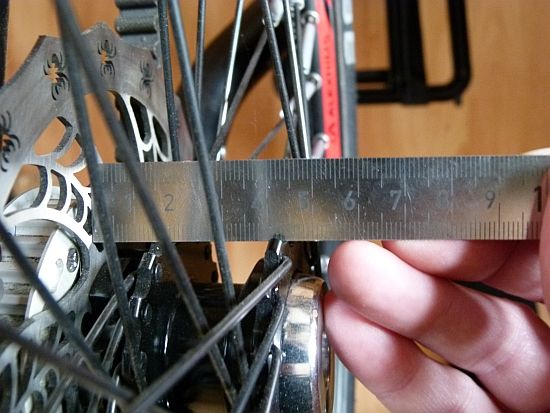

All you need are two (steel) rulers ore anything similar.

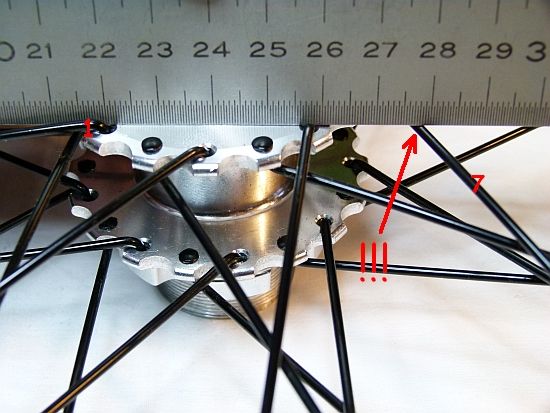

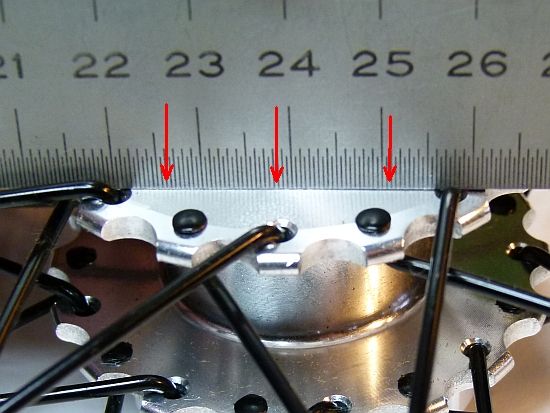

Look for three outer spokes and push the edge of the ruler onto the outer side of the hub flange,

directly below the counterpart of the magnet - like cutting 5 spoke holes off the flange.

Now count the spokes, beginning from the one which is most parrallel to the ruler.

The ruler should be very close (or in touch) with the spokes 1 and 5.

Please note: Strida wheels are built sometimes with the leading spokes on the outside and sometimes on the inside of the flanges!

Therefore you have to count either clock- or counterclockwise; depending on the spokes direction of your personal wheel.

Watch out for spoke 7 - it must not touch the ruler!

Once the edge of the ruler is sitting properly on the surface of the hub

you (or better your assistant) can measure the distance to the rim.

I’ve checked that way three original rear wheels, all were between ~ 5 to ~ 9 mm.

Of course will that amount vary due to the trueness of the wheel,

but if yours were, say, ~ 12 - 14 mm around the whole rim,

- then could the reason for your issue be a sloppy built wheel.

Caution: Different rim widths would require a new calculation of the correct hub flange to rim offset.

To assure that we’re using the same rims you might measure the rim width outside, should be ~ 21,5 mm.

@ BSA,

Thank you for your very detailed illustrations regarding my fender /wheel problem.

I will check it and follow-up in this thread.

@ BSA,

~ 12 - 14 mm around the whole rim

If the above tolerances are not met upon measuring my rim, does it mean I need to do spoke adjustments or wheel alignment?

Oh, amazing…

Seems we’re coming closer to the core… ![]()

I’d say - as there was a problem from the beginning - that’s a classical warranty case (obviously is the wheel out of tolerance).

You mentioned already to have trouble to visit Mighty Velo, but for a warranty claim there will be no alternative, I believe.

It would be also easy to check a rear wheel at the store; if the flange edge/rim edge distance is much lower than on your wheel then should the shop owner/mechanic understand.

Did you mean you want to do spoke adjustment or wheel alignment by yourself?

Of course is that possible, but you’ll need a few tools (trueing stand, spoke key, ruler,…) and moreover that:

A bit feeling in your hands, several hours time, good concentration, a silent working place and a LOT of patience!

Please tell me if you need more info about trueing,

but I would insist on replacement of the wheel(s).

My rear one is also rubbing, noticed it today when riding in the basements at work.

But it’s with a Schwalbe Marathon plus tyre. Also bought the SX in Nov 2013.

On the other hand, the basementfloor isn’t flat, it are all small tiles. So not a smooth ride actually. When riding the streets I don’t notice it rubbing, but then again with the wind these days (and the noise of other traffic) you would need very good ears to hear it…

But the tyre shouldn’t touch anything…wtf?? ![]()

Do you have also tyre width 1,35" (and not 1,5")?

Would it be very much effort for you to check the wheel as mentioned above?

@BSA,

I had a quick check on my wheel /spoke and gap at the rim edge this morning.

First, the ruler ( i used a triangular scale rule) touched the 7th spoke in most of the spokes.Only a few are not touching but the gap is almost a hairline gap only.

2nd, the gaps at the rim edge is (approx) >10mm.

If this can be corrected by spoke adjustments (truing) ,I will have a try on it.

I have a scheduled round island Singapore ride this coming sunday with a group and chinese new year holiday this weekend.Shops are closed until next week.

If I cannot do the adjustments in time, I will cancel my ride.

I will try to send this to Mighty Velo for checks after the holiday.

Thank you for your advise.

Oh, sounds great, I’d really like to attend ![]()

Wouldn’t that be a good opportunity to ask there for advice and/or compare your SX with others locally?

Before you touch the spokes (and loose warranty from Ming)

and I write a few tips for trueing ![]()

please let me suggest two more measurings, both are very easy:

First - to assure that Ming didn’t change the hubs width recently - it would be good to measure from brake disc to the above mentioned outer flange edge; that should be ~ 44 mm.

And second - as a sight from the opposite direction - the distance from tyre to belt; below with Kojak ~ 17 mm, with Innova maybe around 14 - 16 mm (?). I mean below 12 must be the critical border…

Perhaps you are able and willing to try the following too…

Supposed that the wheels of my black one are built correctly they should be nicely in line to each other and also with the frame.

That can be checked with two “tools” (say rails), I took straight, square wooden strips of size 26 x 26 mm, but everything which is handy, straight, stiff and at least 1,30 m long does.

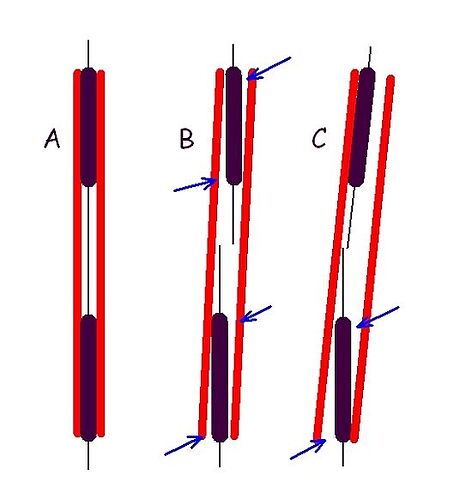

So, for my logical understanding, should after gently pushing the rails together onto the left and right flanks of the tyres (parallel to ground level at a height of 5-10 cm) the situation should look like

- either figure A

(The wheels are in line, there is no gap visible) - or figure B

(Wheels are staggered, it is not possible to avoid gaps at the blue arrowed points)

Even with little steering movements (figure C) there will always be a gap, I believe…

What do you think?

P.S.:

Just called Mike (my friend and bike dealer, engineer) and discussed the issue, he meant also that the rail testing method will be recommendable.

He told me furthermore that a small misalignment of the wheels must not automatically cause a tactile left or right steering preference!

(Which was actually one of my first thoughts, as you will remember.)

Checked today another two rear wheels at my local Strida store (same rulers, same method as above):

At an 18" EVO about 6-7 mm,

on a SX a bit more, ~ 8-9 mm, but all around anyway within one cm.

I’ll take back my statements.

The noise I heard wasn’t from the tire rubbing the fender, turned the bike upsidedown today and it has more then enough clearance.

The noise I heard was from the belt rubbing against the tensioner.

@BSA,

I backed-out from the round island ride last Sunday ![]()

This is a mix bike ride of different brands, sizes and types and I’m the only one using Strida ![]()

Over the weekend, I had taken the opportunity to measure the rear wheel (with a triangular scale rule) and would like to note that the dimensions/gaps around the wheel is 8~9 mm.It looks fine basing on the said dimensions, however upon reading the latest thread on other ways of checking alignments, and dimensions from tyre to the belt, and wheel alignment with the use of straight edge , I have not done these checks.I will try to do the same checks.

I did a check of the front wheel also, and found that there is a truing difference of 3mm in one part of the wheel. I also noticed some spokes with a loose than normal .I tried adjusting the said 3mm. difference (with a lot of patience and concentration ) and managed to get it to the closest possible. I also noticed a 1mm. shake of the bearing when I pressed the side of the wheel.(the rear wheel does not have this shake feeling).

And did you do anything?

If the bearing itself made a noise it might be damaged…

Unfortunately are those bearings of a weird size and minor quality - not the best combination.

At least they’re really cheap ![]()

May I ask why you’re feeling sad?

Is it because you (maybe) noticed some limitations of “her” compared to usual bikes during your ride?

Perhaps you just need a different angle of sight, what about that:

You were the only one with Strida - well, so you also had an exclusive status, no?

I mean that’s not awkward - hej; that’s cool, men ![]()

![]()

Respect for having enough courage to true your wheel!

At the end of this post are a few links with additional wheel (trueing) informations ![]()

@BSA:

I had a mix feeling about backing-out of the Sunday Ride,not because i’m the only Strida riding cyclist out there.I knew that I can complete the ride with my Strida no matter what.It’s just that some of the seasoned riders aimed to finished at a faster time ,which I think is not safe for me to do.

Previously, had a 60kms ride with the same group of mix bikes and proven that Strida can make it in time . ![]()

Some of them are simply amazed, curiously asking about my Strida, because it coped well with all the road conditions and not left-out in the ride.Some even tried to ride my Strida after the event.It was a leisure ride and time of finishing is not much of importance ,but of course the organizers had a targeted time to finish the ride.

I have been busy at work after the long weekend and have not done the measurements of the belt to flange .I will post it this week.

Meantime, still enjoying my daily morning ride with my Strida of 10-12 kms at Park before I go to work.

It was just noise from the belt itself touching the metal of the bearing. The bearing isn’t grinding or anything. Contactnoise ![]()

I was only able to hear it when riding trough the basements at work, so when there’s no wind or other noise involved…