@ Bietrume:

Many thanks for the inspiration

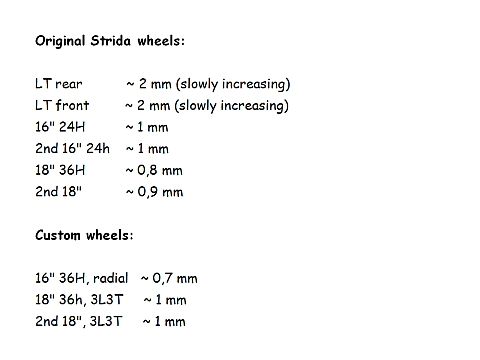

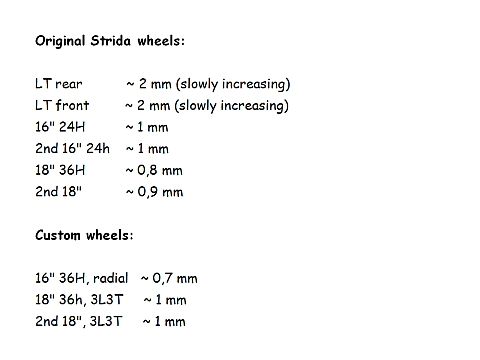

Below the results of the wheel stiffness experiment;

but first a few words about the test setup:

A common Strida rear axle was clamped firmly with a vise, the main measuring clock,

magnetically clamped to a ~ 25 kg steel plate, is touching the rim from the bottom, as close as possible to the weight.

The feeler of the second measuring clockwork is in touch to the axle via an Allen bolt to check the axle bending.

The axle bent under load with all 16" wheels 1 tenth mm; the clockwork’s arm is sadly too short for 18" wheels.

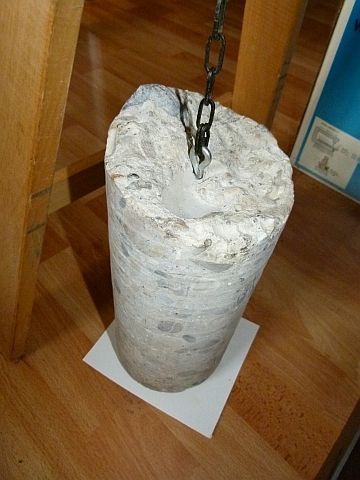

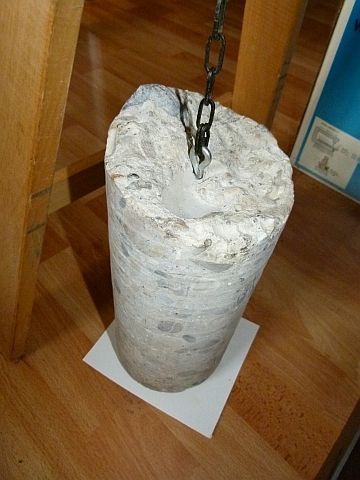

The weight (a concrete drill core) of ~ 7,2 kilogram can be attached via a steel hook, below the hook an aluminium pad, for centering of the weight in the middle of the rim’s flank and to protect the rim.

Applying the weight on different points of the rim (above and vice-versa the valve hole, between or directly above spoke nipples) did not affect the bending of the rim (much, within 1 tenth mm).

Please note:

All checked wheels are rear wheels, except the LT plastic front wheel.

All Original Strida wheels (of course, except the LT plastic wheels  ),

),

were at least one time trued and their spoke tensions were corrected,

so the results might be slightly different to untouched Original Strida wheels.

An amazing effect can be watched on the plastic LT wheels only:

Once the full weight is applied, the indicator of the clockwork doesn’t really stop at the reached point - slow, but steady the indicator moves along

(I’ve stopped this test within 30 seconds or so…couldn’t watch that, sorry…)

It has to be said that vice-versa the same effect appears:

Once the weight is detached, the clockwork’s indicator will not stop at a particular point, for a short time it will move slowly further.

These movements were within a range of 3 tenth of a millimeter.

Do you think the above is clear enough?

![]()