Hi all

I would appreciate any engineers’ (or similar experts’) opinions about this.

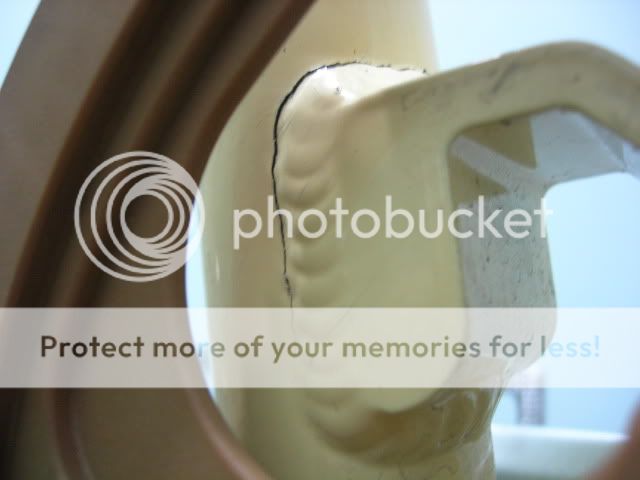

As the subject states, the bottom tube on my Strida 5.2 recently broke. The interesting thing is, the break looks extremely similar to the fracture suffered by the fake Strida, as posted by Amuro on another thread ([url]Keep Strida Original - say NO to Fakes! - #103 by StridaD]). Same place, just above the front weld where the pedal bracket is welded to the bottom tube.

After the break occurred, the steering pin onto which the bottom tube is locked was no longer vertical. It was angled back towards the rear of the bike, about 45 degrees or so from the original position. But it was still so tight that I could not budge it. It appears undamaged.

So I was wondering what could have caused this. Would the tube have cracked and thus put pressure on the pin, causing it to budge? Or would the pin have budged, causing the tube to crack? And as for the pin, how could it have budged when it seems so tight? And why is it even movable anyway, wouldn’t it be better if the pin were also welded in place? Is it even possible to achieve 20-25 Nm with a normal Allen key?

I assume that this is a rare occurrence, as I haven’t found any other such reports on the 'net. But I do hope this doesn’t point to any sort of inherent flaw in the design.

As an aside, I would like to thank and praise Strida Europe for their excellent customer service, they very promptly honoured the frame warranty after seeing photos and I received a replacement bike within a week. Interesting to see the differences between the LX and the 5.2, but that’s another story. ![]()